One of the most important factors concerning efficient ice rink design is elimination of moisture loads. Moisture enters through outdoor air and evaporating floodwater from the ice resurfacer. Excess humidity increases the risk of corrosion, growth of mold and fungi, while reducing the life expectancy of the rinks mechanical equipment.

To combat the issues of high humidity levels, we propose two primary ways of handling air moisture.

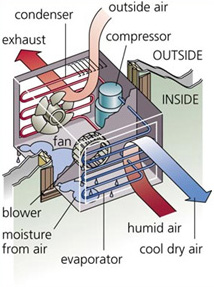

Mechanical Dehumidification

Mechanical dehumidifiers cool the air below its dew point to eliminate the possibility of condensation. To accomplish this, the mechanical unit cools air over a cooling coil causing a portion of the moisture in the air to condensate on the coil itself.

Quality Features:

- Engineered for high airflow with design techniques to maintain optimum airflow through the dehumidification coil and maximize moisture removal

- True sub-cooling circuit to improve system efficiency

- Units are factory assembled, wired, charged and tested

- Indoor packaged dehumidifiers specifically designed for arenas

- Operate on all voltages and can be mounted indoors or out, on a stand or suspended from the ceiling

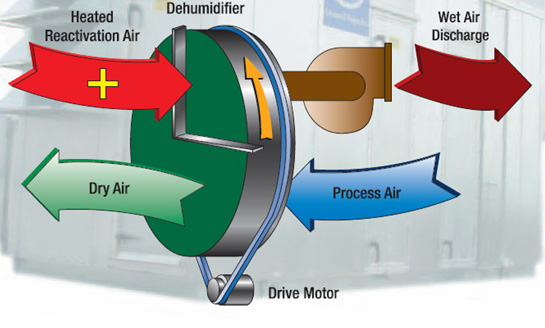

Desiccant Dehumidification

The other type of moisture removal for ice rinks is achieved through chemical dehumidification. In the case of a desiccant dehumidifier, the desiccant wheel contains absorbent materials that extract the moisture. The moisture wheel is a slowly rotating disk that is filled with an absorbent gel. As the wheel slowly turns, the absorbent material is conditioned with warm air where the moisture is transferred outside the facility.

Quality Features:

- Few moving parts

- Low maintenance

- Very dry air

- Multiple sizes to accommodate multiple rink applications

- Limited ductwork needed

- Operate on multiple voltages

- Can be placed inside or outside